History

1983-1988 Concept

The Negative Pressure Supercharging concept was first conceived 1983 in Sydney

Australia by Alexander Chabry, a 21 year old self-taught engineer with a remarkable

insight into the fluid dynamics of the conventional 4-stroke engine. He was inspired by

the fast acceleration produced by the low revving 225 Chrysler slant 6 and the massive

towing power (torque) produced by heavy trucks. He figured cars could use low rpm torque

instead of high rpm horsepower to substantially improve acceleration and fuel economy.

Alex explored this

new supercharging concept for over 5 years to work out its basic operating principles

before he applied it to the 4-stroke engine. Although the concept is radically different

to conventional principles, he knew it will work because the idea is based on sound

physics. He was proven right in 1997 when the Negative Pressure Supercharging concept

became a working reality. But what Alex didn't know is that it will take more than 15

years to figure out the complex fluid dynamics of Negative Pressure Supercharging to make

it work in the 4-stroke engine. Alex explored this

new supercharging concept for over 5 years to work out its basic operating principles

before he applied it to the 4-stroke engine. Although the concept is radically different

to conventional principles, he knew it will work because the idea is based on sound

physics. He was proven right in 1997 when the Negative Pressure Supercharging concept

became a working reality. But what Alex didn't know is that it will take more than 15

years to figure out the complex fluid dynamics of Negative Pressure Supercharging to make

it work in the 4-stroke engine.

It's interesting to note that in 1876 the inventor of the 4-stroke engine was not the

steam locomotive companies but instead Nicolaus August Otto a brilliant self-taught

engineer. The situation is the same today. Its not car companies that have invented this

revolutionary new supercharging process that makes the 4-stroke engine supercharge itself

using NO air pump but again a brilliant self-taught engineer, Alexander Chabry.

Top of page

1988-1993 Development

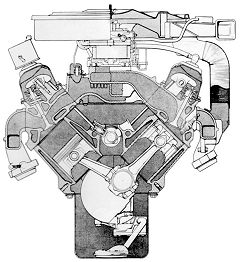

Development of the Negative Pressure Supercharging concept began in October 1988 on an

early 360ci Chrysler small block that was fully rebuilt using standard parts and the

Negative Pressure Supercharging headers, valve timing, ignition timing and modified heads

and intake manifold.

The mechanically simple design of the 360 allowed us to go back to basics in order to

develop the complex fluid dynamics of this new supercharging process and the heavy duty

construction of the 360 allowed the engine to operate reliably for 17 years and 50,000

miles (80,000 km) of extensive testing with no failure to any engine parts. However, over

the 17 years the 360 broke 3 torque converters and 1 flex band in the transmission due to

the massive torque produced by the Negative Pressure Supercharging process.

We chose a standard

1972 360 Chrysler small block to develop this new supercharging concept because it's a

mechanically simple heavy duty pushrod engine that features a number of remarkable

technological advancements not found on other more popular thin wall construction V8's

produced over the past 30 years such as, We chose a standard

1972 360 Chrysler small block to develop this new supercharging concept because it's a

mechanically simple heavy duty pushrod engine that features a number of remarkable

technological advancements not found on other more popular thin wall construction V8's

produced over the past 30 years such as,

- stronger thick wall construction block and heads,

- larger cylinder head and crank main end bolts,

- heavy duty rocker shaft valve train,

- high flow 23° intake ports,

- valves that open at the centre of the cylinder to minimise valve shrouding and increase

air flow,

- larger diameter and taller valve springs that allow more lift and higher spring

pressures with fast acting cams,

- centrally located spark plugs in combustion chamber that produce a superior burn and

more power,

- wider diameter camshaft that minimises cam flex and optimises valve timing,

- larger diameter cam lifters (tappets) that allow more valve lift and much faster opening

valves to increase air flow and produce more power,

- camshaft thrust plate that prevents cam walk and damage to cam lobes, lifters (tappets)

and timing chain,

- stronger crankshaft with larger bearings to handle high torque loads,

- stronger piston pins with a larger diameter to handle high torque loads,

- larger heavy duty con-rods to handle high torque loads,

- higher crank to con-rod ratio that produces more torque,

- electronic ignition distributor with heavy advance weights that stabilise ignition

timing and eliminate spark scatter.

Over the next 5 years development of the Negative Pressure Supercharging process

involved extensive trial and error testing of hundreds of different combinations,

increasing the speed of the exhaust gas from the common 300 ft/sec to a faster 450 ft/sec,

advancing the valve timing events, using radical ignition advance curves and a compact

megaphone Tri-Y exhaust header with small pipes half the size and one third the length of

conventional headers. By mid 1993 a portion of the Negative Pressure Supercharging concept

began to work for the first time and it was no longer a concept. During 1993 we also

established Patents worldwide as the inventor of the Negative Pressure Supercharging

technology.

Top of page

1993-1995 Development

The huge increase in torque produced by the Negative Pressure Supercharging process,

encouraged us to use even smaller diameter header pipes in order to produce a higher gas

speed. As a result, the gas velocity was twice the speed produced by conventional headers.

However, the higher gas velocity changed the optimum fluid dynamics (air and gas flow) and

prevented this supercharging process from working.

After 2 years of trial and error testing, we found that when the speed of the exhaust gas

was increased in the header from 450 ft/sec to a much faster 600 ft/sec, even less exhaust

valve lift and overlap duration is required and 4 key areas of the engine that control the

fluid dynamics (air and gas flow) need to be synchronised together for the Negative

Pressure Supercharging process to work. This was an exciting breakthrough. It would have

been almost impossible to figure out how this new supercharging process works if we had

not discovered that several unique valve timing events need to work in synch.

Top of page

1995-1997 Development to Success

We continued to test many other different combinations and to refine the Negative

Pressure Supercharging process with this new information. We found a total of 8 key areas

of the camshaft, cylinder head and exhaust header need to be synchronised together for

this new supercharging process to work at optimum and increase the supercharging effect.

On 10 December 1997 the Negative Pressure Supercharging process officially became

a working reality.

We approached a number of car makers around the world to see if they were interested in

the Negative Pressure Supercharging technology and found a disturbing trend. Car makers

are not interested in any new engine technology that comes from outside their company even

if it's more advanced and cost-effective to produce. Car makers would rather make new car

engines more mechanically complex each year using their own technology to improve

performance than pay for highly advanced technology that originates outside their company.

We were disappointed but it did not worry us that car makers have closed their doors to

new engine technology. New cars are a very small market and Negative Pressure

Supercharging can be applied to the 700 million engines currently being used worldwide in

cars, pickups, RV's, trucks, buses, motorcycles, boats, tractors to propeller planes

produced from 1900 to the present time.

Top of page

1997-1999 Refinement

We made further refinements and found the Negative Pressure Supercharging process also

requires hot air induction and a cold water temperature to work at optimum and increase

the supercharging effect. However, due to the many inquiries we received for Negative

Supercharging Kits we gradually stopped most of the development and focused our resources

to tooling up to produce Kits.

Top of page

1999-2002 Tooling Up

During this

period we set up the tooling to produce the special parts of the Negative Supercharging

Kits for initially 318 360 Chrysler small blocks and 245 265 Hemi 6 engines. However, one

of our major tools was sabotaged in 2003 to prevent us from releasing this new

supercharging technology which forced us to put the Hemi 6 Kits on hold. We also organised

a number of aftermarket manufacturers to produce or supply heavy duty high quality parts

for the Negative Supercharging Kits. This was required to keep the engines reliable with

the massive torque produced by Negative Pressure Supercharging. During this

period we set up the tooling to produce the special parts of the Negative Supercharging

Kits for initially 318 360 Chrysler small blocks and 245 265 Hemi 6 engines. However, one

of our major tools was sabotaged in 2003 to prevent us from releasing this new

supercharging technology which forced us to put the Hemi 6 Kits on hold. We also organised

a number of aftermarket manufacturers to produce or supply heavy duty high quality parts

for the Negative Supercharging Kits. This was required to keep the engines reliable with

the massive torque produced by Negative Pressure Supercharging.

We approached a number of well known performance aftermarket manufacturers in the US to

set up Negative Supercharging Kits for the wide range of engines in the market. We offered

to demonstrate the massive torque and the many performance improvements produced by a 360

Chrysler small block fitted with the Negative Pressure Supercharging process.

Unfortunately, the performance aftermarket manufacturers were

not interested to see our 360

prototype engine because they figured this new supercharging

technology is so radical it couldn't possibly work.

This had no bearing on the viability of the Negative

Pressure Supercharging technology. Instead it reflects

the narrow-minded attitude of today's automotive engineers

who have become so familiar with the operating principles

of the 4-stroke engine, they refuse to accept any new

technology that works outside the square.

This was a disappointing setback to making Negative Supercharging Kits available for the

wide range of engines in the market. But at the same time we were flattered that the

Negative Pressure Supercharging process is so highly advanced it works beyond the

comprehension of the greatest minds in the automotive industry. Despite this obstacle we

continued to set up Negative Supercharging Kits for Chrysler small blocks.

Top of page

2003-2004 Tooling Up to Production

Negative Supercharging Kits were scheduled to be introduced in March 2003 for initially

318 360 Chrysler small blocks. All the tooling was completed and over 100 Negative

Supercharging Kits were produced. However, we were not able to produce the Thermocharger

air cleaner housing which prevented us from releasing the Kits.

This was due to a corrupt business that sabotaged the Negative Supercharging Kits by

intentionally throwing out our Thermocharger tooling to prevent us from releasing this new

supercharging technology. This unfortunate event set us back 2 years. The photos show one

of only 3 original LHD Thermochargers produced before they threw out the tooling. The

original RHD Thermocharger never made it to production. We had no choice but to start

again from scratch and set up the new tooling for the LHD and RHD Thermocharger so

Negative Supercharging Kits will be available in 2005 for Chrysler small blocks, left and

right hand drive vehicles and for other make of engines in the future.

Top of page

2005 Production

Over the

past 17 years we invested millions and struggled to develop the complex process of the

Negative Pressure Supercharging technology using are own resources and with no financial

help from investors or government funding. We also used our own resources to set up the

tooling to produce Negative Supercharging Kits for 318 360 Chrysler small blocks. Over the

past 17 years we invested millions and struggled to develop the complex process of the

Negative Pressure Supercharging technology using are own resources and with no financial

help from investors or government funding. We also used our own resources to set up the

tooling to produce Negative Supercharging Kits for 318 360 Chrysler small blocks.

Therefore, we are proud to introduce Negative Pressure Supercharging for the first time

this year as a revolutionary new technology that makes the engine supercharge itself using

NO air pump and the technology was financed and developed exclusively by Impulse Engine

Technology P/L in Australia.

Negative Supercharging Kits will be available in 2005 for initially 318 360 Chrysler small

blocks. Kits for other Chrysler, GM and Ford 6 and V8 engines will be available in the

future. Negative Supercharging Kits are made in Australia.

Top of page

2007 Tooling Up for Other Engines

As Negative Supercharging Kits demonstrate their ability to transform engines into

powerful fuel efficient power plants that produce the violent acceleration of race cars

and the massive towing power of trucks, more people will become interested in the many

performance advantages of this new supercharging technology.

This may encourage the performance aftermarket manufacturers to produce Negative

Supercharging Kits for the many different make and size of engines in the market. However,

if this does not happen we will endeavor to set up Negative Supercharging Kits for 400 440

Chrysler big blocks, 245 265 Chrysler Hemi 6, 198 225 Chrysler Slant 6, 327 350 Chevy

small blocks and 302 351 Ford small blocks.

Top of page

2008 and the Future

In the future we plan to set up Negative Supercharging Kits for more applications that

include GM and Ford big blocks, Harley Davidson motorcycle engines, V8 inboard marine

engines and Continental or Lycoming propeller plane engines.

As more businesses take an interest in the performance advantages of this new

supercharging technology and set up Negative Supercharging Kits for the many different

engines in the market, Negative Pressure Supercharging will be available for a wider range

of engines in the future.

Negative Pressure Supercharging is set to become the engine technology of the

future for the following reasons:

- It's a highly advanced process that makes the engine supercharge itself using NO air

pump

- It combines the performance advantages of 3 different engines into one engine,

1) the violent acceleration of a race car,

2) the smooth idle and fuel economy of a family car, and

3) the massive towing power of a truck from idle

- It allows smaller engines of half the capacity to produce the same acceleration and

towing power as much larger engines while substantially improving fuel economy and

emissions

- It costs 1/3 the price of conventional supercharger or turbocharger air pump systems

- It can be easily applied to every car, pickup, RV, truck, bus, motorcycle, boat, tractor

to propeller plane engine produced from 1900-2007

| Impulse Engine Technology

P/L |

PO Box 986 Randwick NSW 2031 Australia

Ph: (02) 9398 5544

Fax: (02) 9398 5644

International: Ph: +(612) 9398 5544

Fax: +(612) 9398 5644

Email Us

Inventor of Negative Pressure Supercharging

|

|