Impulse Engine Technology

PO Box 986 • Randwick NSW 2031 • Australia

Ph: (612) 9398 5544 • Fax: (612) 9398 5644

|

Press Release

|

For Immediate Release

4 July, 2005

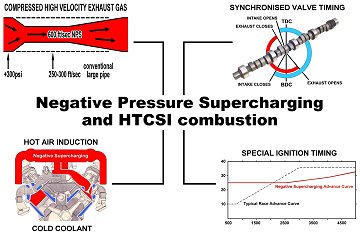

Negative Pressure Supercharging

and HTCSI combustion

Impulse Engine Technology is excited to introduce Negative Pressure Supercharging a revolutionary new clean burn Homogenous Thermal Charge Spark Ignition (HTCSI) supercharging combustion process that substantially improves torque, acceleration, towing, fuel mileage and emissions of OLDER and NEW vehicles from carburetion, fuel injection, gas to diesel. Impulse Engine Technology is excited to introduce Negative Pressure Supercharging a revolutionary new clean burn Homogenous Thermal Charge Spark Ignition (HTCSI) supercharging combustion process that substantially improves torque, acceleration, towing, fuel mileage and emissions of OLDER and NEW vehicles from carburetion, fuel injection, gas to diesel.

Negative Pressure Supercharging (NPS) does NOT use air pumps or complex parts. Instead NPS uses a unique combination of mechanically simple parts and highly advanced processes such as Compressed High Velocity Exhaust Gas (CHVEG) and Synchronised Valve Timing (SVT) to supercharge the engine and substantially improve fuel mileage and emissions.

CHVEG produces a super vacuum which pulls a larger intake charge into the engine while SVT traps the super vacuum in the cylinder during the exhaust stroke and moves it to the intake stroke during the overlap period. This allows the super vacuum to pull a larger intake charge into the engine BEFORE the piston pulls the intake charge into the cylinder. The super vacuum also creates a much greater pressure difference between the cylinder and atmosphere which produces such violent air turbulence it creates a homogenous intake charge.

By increasing the air induction temperature to 40-80°C (105-175°F) it causes the homogenous intake charge to increase the speed of combustion to just BEFORE the point of self ignition. To prevent self ignition the water temperature is reduced to 43-50°C (110-122°F) in conjunction with less ignition advance and cold spark plugs. Despite the cooler water temperature the engine and combustion run hot, only the water passages run cooler. This produces a very fast and clean burn that is controlled mechanically. By increasing the air induction temperature to 40-80°C (105-175°F) it causes the homogenous intake charge to increase the speed of combustion to just BEFORE the point of self ignition. To prevent self ignition the water temperature is reduced to 43-50°C (110-122°F) in conjunction with less ignition advance and cold spark plugs. Despite the cooler water temperature the engine and combustion run hot, only the water passages run cooler. This produces a very fast and clean burn that is controlled mechanically.

As a result NPS and hot air induction produce a Homogenous Thermal Charge Spark Ignition (HTCSI) supercharging combustion process that substantially improves engine and combustion efficiency. Because NPS and HTCSI combustion is controlled mechanically it allows this new supercharging combustion process to be easily applied to older and new vehicles from carburetion, gas to fuel injection using bolt-on kits. NPS and HTCSI combustion can even be applied to diesels using bolt-on kits but the process uses compression ignition instead of a spark.

For more information about...

Benefits of NPS and HTCSI combustion...

|

•

|

Substantially improves power, fuel mileage and emissions of OLDER and NEW vehicles from cars, pickups, RV's, trucks, motorcycles, boats to propeller planes

|

|

•

|

Supercharges the engine using a super vacuum and NO air pump

|

|

•

|

Produces faster acceleration using lower rpm and less fuel

|

|

•

|

Doubles torque and towing power from idle to midrange

|

|

•

|

Increases fuel mileage by 30%

|

|

•

|

Makes carbureted V8's run cleaner than modern fuel injected 4 cylinder engines

|

|

•

|

Runs on low octane fuel or alternative fuels

|

|

•

|

Allows engines of half the capacity to produce the same power of larger engines

|

|

•

|

Works at all throttle positions and rpm

|

|

•

|

Works without computers or complex parts but they may be used to enhance NPS and HTCSI combustion

|

|

•

|

Uses mechanically simple parts that cost much less than mechanically complex parts and technologies

|

|

•

|

Can be easily applied to carbureted, fuel injected, gas and diesel engines using bolt-on kits

|

The only competition NPS and HTCSI combustion currently has in terms of reducing emissions by way of improving combustion efficiency is Homogenous Charge Compression Ignition (HCCI) combustion. The major difference between HTCSI and HCCI combustion is that...

HTCSI combustion increases the speed of combustion to just BEFORE the point of self ignition using a supercharged homogenous intake charge and hot air induction which is controlled by a cold cooling system, special ignition timing, cold spark plugs and mechanically simple parts. This allows HTCSI combustion to work on any vehicle without the need for computers and mechanically complex parts. Whereas...

HCCI combustion increases the speed of combustion to the point of self ignition using a naturally aspirated homogenous intake charge and hot air induction which is controlled by computers and mechanically complex parts. However, HCCI combustion has a number of drawbacks that make it very expensive and impractical for use in motor vehicles. For example, HCCI combustion works at ONLY one throttle position and one rpm while at all other throttle positions and rpm the engine uses normal poor combustion. Also, HCCI combustion is very difficult to control, does NOT work without computers or mechanically complex parts, does NOT work with older engines or diesels and does NOT supercharge the engine or increase fuel mileage by 30% like NPS and HTCSI combustion.

Therefore, NPS and HTCSI combustion is a far more advanced and affordable technology that can be applied to OLDER vehicles using bolt-on kits and to NEW vehicles during production to substantially improve power, fuel mileage and emissions over conventional or other technologies.

For more information please visit http://www.impulsengine.com

| Impulse Engine Technology

P/L |

PO Box 986 Randwick NSW 2031 Australia

Ph: (02) 9398 5544

Fax: (02) 9398 5644

International: Ph: +(612) 9398 5544

Fax: +(612) 9398 5644

Email Us

Inventor of Negative Pressure Supercharging

|

|