|

Ultra Fast Burn

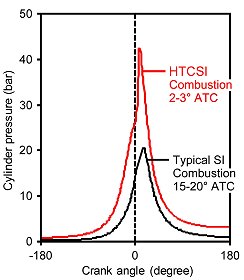

NEW Homogeneous Thermal Charge Spark Ignition (HTCSI) combustion produces more power, fuel economy and cleaner burn by increasing the speed, pressure and temperature of combustion

|

|

|

Produced by a combination of new processes

• NPS - Negative Pressure

Supercharging

• HPDT - High Pressure Differential

Turbulence

• HAI - Hot Air Induction

|

|

|

|

Produces a much faster burn and a lot more combustion pressure earlier After Top Centre than typical spark ignition combustion.

|

|

|

|

|

Controlled by a unique combination of mechanically simple parts and systems

• Special ignition timing with less

advance

• Cold cooling system

• Cold spark plugs

• Low compression

• Open chamber heads

|

|

|

|

• Uses the above combination of

mechanically simple parts and

systems to allow the faster and

hotter burn of HTCSI combustion to

produce more power and prevent

pre-ignition (pinging)

• Can be easily applied to all

engines...

• old or new

• mechanically simple or complex

• carbureted or fuel injected

• Does NOT need computers or

mechanically complex parts but

they may be used to enhance

HTCSI combustion

|

|

|

HTCSI combustion is produced by a combination of new processes that comprise of...

|

•

|

NPS ? Negative Pressure Supercharging

Substantially reduces the pressure (increases vacuum) in the cylinder which produces a much greater pressure difference between atmospheric and cylinder pressure. As a result this,

|

1)

|

Pulls a larger volume of air into the engine.

|

|

2)

|

Increases the air velocity of the intake charge.

|

|

3)

|

Produces high pressure differential turbulence.

|

|

•

|

HPDT ? High Pressure Differential Turbulence

Produces violent air turbulence with NO restriction to air flow. As a result this completely mixes the air fuel mixture together to produce a more uniform homogeneous intake charge than direct injection, high swirl intake ports, close chamber heads and higher compression.

|

•

|

HAI ? Hot Air Induction

|

1)

|

Increases the air induction temperature to just BEFORE the point of self ignition.

|

|

2)

|

Increases the speed and pressure of combustion.

|

|

3)

|

Vapourises the fuel into a gas which uses less fuel and burns much cleaner.

|

|

4)

|

Produces more power than cold air induction. This is because, A) the increase in power produced by the faster burn and higher combustion pressure of the hot intake charge is much greater than the loss produced by less dense hot air and B) the combination of parts and systems shown below allow the hot intake charge to produce more power and prevent pre-ignition (pinging). For more details see Hot Air Induction

|

|

HTCSI combustion is controlled by a unique combination of mechanically simple parts and systems to allow the faster and hotter burn of HTCSI combustion to produce more power and prevent pre-ignition (pinging)

|

•

|

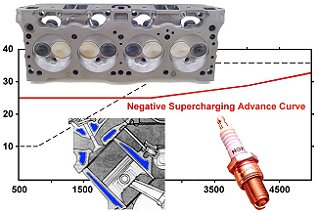

Special ignition timing with less advance

Special ignition timing with 12° less advance allows the faster burn of the hot intake charge to increase combustion pressure (torque) and prevent pre-ignition (pinging). For more details see Ignition Timing

|

|

•

|

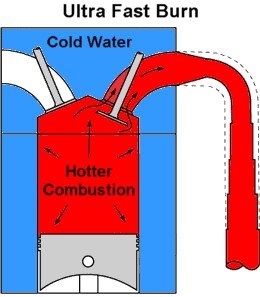

Cold cooling system

Cold water with 43-50°C (110-122°F) temperature prevents the hotter combustion produced by the hot intake charge from exceeding the optimum temperature and igniting prematurely. NOTE: The engine runs HOT with cold water and HTCSI combustion. ONLY the water passages run cooler. For more details see Cold Cooling System

|

•

|

Cold spark plugs

|

|

|

Cold spark plugs with 5 steps colder operating temperature prevent the faster burn of the hot intake charge from igniting prematurely. For more details see Cold Spark Plugs

|

•

|

Low compression and Open chamber heads

Low 8.0 - 8.5:1 compression and open chamber heads prevent the hot intake charge from igniting prematurely during compression.

|

Systems considered as high performance in modern engines with slow burn combustion reduce power and produce pre-ignition (pinging) with the faster and hotter burn of HTCSI combustion

Ignition timing with more advance Ignition timing with more advance

Cold air induction Cold air induction

Hot cooling system Hot cooling system

Hot spark plugs Hot spark plugs

High compression High compression

Close chamber heads Close chamber heads

HTCSI combustion makes the engine run cooler and converts more thermal energy into mechanical power

Both slow burn (cold air) and fast burn (hot air) produce tremendous heat during combustion.

However,

Slow burn (cold air) produces less heat for a longer period of time which...

|

•

|

Transfers MORE heat into the cooling system which makes the engine run HOTTER

|

|

•

|

Converts LESS combustion heat into mechanical power

|

|

•

|

Allows the valves to run HOTTER which can damage the exhaust valve and seat

|

Whereas,

Fast burn (hot air) produces more heat for a shorter period of time which...

|

•

|

Transfers LESS heat into the cooling system which makes the engine run COOLER

|

|

•

|

Converts MORE combustion heat into mechanical power

|

|

•

|

Allows the valves to run COOLER and prevents the exhaust valve and seat from burning

|

However, fast burn (hot air) must be used with cold water to...

|

•

|

Help keep the valves cooler by absorbing more heat from the valve while the valve is closed than does hot water

|

|

•

|

Maintain the optimum hotter combustion temperature

|

|

•

|

Prevent pre-ignition (pinging)

|

HTCSI combustion produces a constant hot temperature from part to full throttle which...

|

•

|

Reduces toxic emissions

|

|

•

|

Eliminates the need for emission controls

|

|

•

|

Protects the spark plugs from rapid erosion

|

|

•

|

Allows the use of low cost spark plugs

|

|

•

|

Allows engines to be mechanically simple which substantially reduce the cost of vehicles

|

Conventional combustion used by today's wonder engines substantially increases combustion temperature from part to full throttle which...

|

•

|

Increases toxic emissions

|

|

•

|

Requires using emission controls

|

|

•

|

Rapidly erodes the spark plugs

|

|

•

|

Requires using expensive spark plugs

|

|

•

|

Requires engines to be more mechanically complex in order to reduce emissions which substantially increase the cost of vehicles. Unfortunately this trend will continue until carmakers realise they can now make engines mechanically simple and run cleaner with HTCSI combustion

|

NOTE

The increase in combustion temperature produced by today's wonder engines during the transition from part to full throttle is colder than the hotter combustion produced by HTCSI combustion.

HTCSI combustion enhances Negative Pressure Supercharging

The hotter combustion produced by HTCSI combustion increases the temperature of the exhaust gas which further increases the high gas velocity produced by the Negative Pressure Supercharging header. This further reduces the pressure (increases vacuum) in the cylinder at the end of the exhaust stroke which pulls even more air into the engine. For more details see Exhaust Headers

| Impulse Engine Technology

P/L |

PO Box 986 Randwick NSW 2031 Australia

Ph: (02) 9398 5544

Fax: (02) 9398 5644

International: Ph: +(612) 9398 5544

Fax: +(612) 9398 5644

Email Us

Inventor of Negative Pressure Supercharging

|

|