|

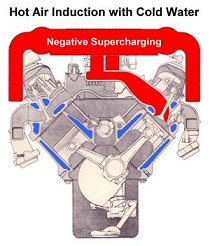

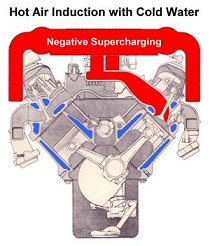

Hot Air Induction and Cold Water

NEW Hot Air Induction and Cold Cooling System uses...

|

•

|

HOT AIR to increase the speed of combustion to just BEFORE the point of self-ignition

|

|

•

|

COLD WATER to maintain the optimum burn rate and combustion temperature of the hotter intake charge and prevent it from igniting prematurely

|

|

NOTE

Hot Air Induction.................

|

refers to air induction temperatures ABOVE 40°C (104°F)

|

|

Cold Cooling System...........

|

refers to water temperatures 40-50°C (104-122°F)

|

Hot Air Induction produces MORE torque and horsepower than Cold Air Induction more details

Engine runs HOT with cold water and hot air induction...ONLY the water passages run cold more details

Hot Air Induction is also produced by supercharger and turbocharger air pumps more details

|

|

Hot Air Induction and Cold Water

The larger intake charge pulled into the cylinder by Negative Pressure Supercharging burns slower and is more difficult to ignite the colder the air induction temperature BELOW 40?C (104?F). Therefore, the air induction temperature is increased ABOVE 40?C (104?F) to increase the speed of combustion to just before the point of self-ignition. This makes the larger intake charge burn much faster and produce more combustion pressure (torque). For more details see Ultra Fast Burn

However, hot water temperatures between 60-110?C (140-230?F) cause the hotter intake charge to exceed the optimum burn rate and combustion temperature which substantially reduces power. Therefore, the water temperature is reduced to 40-50?C (104-122?F) in order to maintain the optimum burn rate and combustion temperature with hot air induction. Even though the water temperature is much cooler with hot air induction the engine runs HOT. For more details see Engine runs HOT with cold water and hot air induction

|

Also, the much faster burn produced by hot air induction uses less ignition advance to prevent pre-ignition (pinging) and produce more power. For more details see NPS Ignition Timing

For example,

|

If air induction temperature...

|

If water temperature...

|

|

EXCEEDS 50°C (122°F)

|

Engine produces more power the hotter the air induction temperature is increased from 50-121°C (122-250°F) but the water temperature must NOT exceed 50°C (122°F).

|

Engine produces less power the hotter the water temperature ABOVE 50°C (122°F).

|

|

FALLS BELOW 40°C (104°F)

|

Engine produces less power the colder the air induction temperature is reduced BELOW 40°C (104°F) even if the water temperature is increased to above 82°C (180°F).

|

Engine produces less power the colder the water temperature BELOW 40°C (104°F).

|

Engine runs HOT with cold water and hot air induction?ONLY the water passages run cold

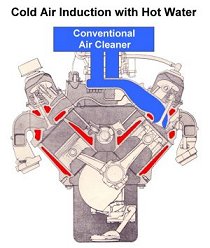

Hot Air Induction produces MORE torque and horsepower than Cold Air Induction For example,

|

If one cylinder of a typical V8 engine is filled with a cold intake charge and another cylinder is filled with a hot intake charge of equal volume, the cylinder with the cold intake charge is more dense which produces more power. This is true ONLY when the cold intake charge is used with hot coolant because the hot water increases the temperature of the cold intake charge to the optimum burn rate.

However, the cold intake charge produces LESS power with cold coolant during a cold start or with hot coolant during hot weather. This is because...

|

•

|

Cold water reduces the temperature of the cold intake charge BELOW the optimum burn rate

|

|

•

|

Hot water increases the temperature of the hot intake charge ABOVE the optimum burn rate

|

|

|

|

However, by using cold coolant with a hot intake charge the cold water reduces the temperature of the hot intake charge to the optimum burn rate. This allows the hot intake charge to produce a lot more combustion pressure than a cold intake charge because hot gas burns much faster than cold gas.

Therefore, the engine produces more power with hot air induction because the increase in power produced by the higher combustion pressure of hot gas is much greater than the loss produced by the less dense hot air.

The cold coolant also maintains the optimum combustion temperature with the hotter and faster burn produced by the hot intake charge. This allows the engine to run HOT with cold water and hot air induction...ONLY the water passages run cold.

|

Hot Air Induction is also produced by supercharger and turbocharger air pumps The Negative Pressure Supercharging process has the opposite problem?it reduces the air induction temperature which makes the larger intake charge too cold and difficult to ignite. Therefore, heat is drawn from the exhaust headers to increase the temperature of the intake charge to the optimum burn rate. This produces an intake charge that is hotter than outside temperatures which allows the larger intake charge to burn faster and produce more power. However, because the NPS process uses a Cold Cooling System instead of an intercooler it allows using an even hotter intake charge which produces a further increase in power.

| Impulse Engine Technology

P/L |

PO Box 986 Randwick NSW 2031 Australia

Ph: (02) 9398 5544

Fax: (02) 9398 5644

International: Ph: +(612) 9398 5544

Fax: +(612) 9398 5644

Email Us

Inventor of Negative Pressure Supercharging

|

|