Basic description of parts and processes that work together to produce Negative Pressure Supercharging

For more details see Combination of parts and processes that work together to produce NPS

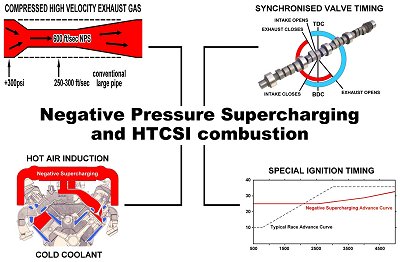

Tri-Y Headers with small short pipes and megaphone collector produce Compressed High Velocity Exhaust Gas

|

|

|

•

|

Substantially reduces the pressure (increases vacuum) in the cylinder during the exhaust stroke

|

|

•

|

Pulls a larger volume of air into the cylinder during the early part of the intake stroke by the lower pressure (higher vacuum) trapped in the combustion chamber during the overlap period with synchronised valve timing

|

|

•

|

Produces a homogenous intake charge as a result of the violent air turbulence produced by the much greater difference in pressure between the cylinder and atmosphere

|

|

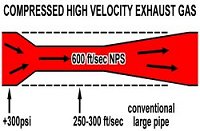

Camshaft with Synchronised Valve Timing, high intake lift and low exhaust lift

|

|

|

•

|

Traps the lower pressure (higher vacuum) in the cylinder at the end of the exhaust stroke by closing the exhaust valve early and using less overlap duration and exhaust valve lift

|

|

•

|

Moves the lower pressure (higher vacuum) to the intake stroke during the overlap period by synchronising the exhaust valve closing, overlap duration and exhaust valve lift events

|

|

•

|

Traps the larger volume of air pulled into the cylinder during the intake stroke by closing the intake valve early

|

|

•

|

Prevents the lower pressure (higher vacuum) from pulling the intake charge into the exhaust system during the overlap period

|

|

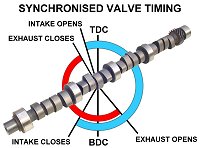

Hot Air Induction housing

|

|

|

•

|

Increases the temperature of the homogenous intake charge

|

|

•

|

Uses hot air to increase the speed of combustion to just BEFORE the point of self ignition

|

|

•

|

Vapourises the liquid fuel into a gas to reduce fuel consumption

|

|

•

|

Produces a faster cleaner burn and more combustion pressure (torque)

|

|

•

|

Reduces the water temperature to maintain the optimum combustion temperature and burn rate with the hotter and faster burn produced by the homogenous hot intake charge

|

|

•

|

Allows the homogenous hot intake charge to produce a faster cleaner burn and more combustion pressure (torque) than a cold intake charge

|

|

•

|

Allows the engine to run HOT with cold water and hot air induction...ONLY the water passages run cold

|

|

|

|

|

•

|

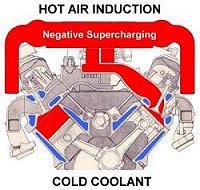

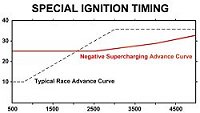

Uses a special advance curve to increase combustion pressure (torque) and prevent the hotter and faster burn produced by the homogenous hot intake charge from igniting prematurely

|

|

| Impulse Engine Technology

P/L |

PO Box 986 Randwick NSW 2031 Australia

Ph: (02) 9398 5544

Fax: (02) 9398 5644

International: Ph: +(612) 9398 5544

Fax: +(612) 9398 5644

Email Us

Inventor of Negative Pressure Supercharging

|

|

|