|

How Negative Pressure Supercharging works compared to standard and race engines

Negative Pressure Supercharging is a highly advanced 6 cycle supercharging combustion process that produces substantially more torque and horsepower and much lower fuel consumption and emissions over a lower and wider rpm range than the old 4 cycle process used by today?s engines

|

Negative Pressure Supercharging

|

|

Standard and Race engines

|

|

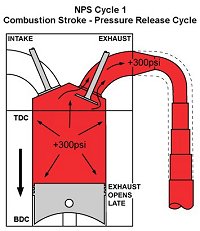

Cycle 1 Combustion Stroke - Pressure Release Cycle

|

|

|

|

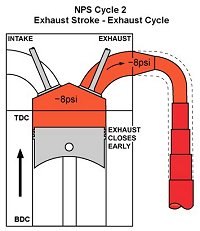

Cycle 2 Exhaust Stroke - Exhaust Cycle

|

=

|

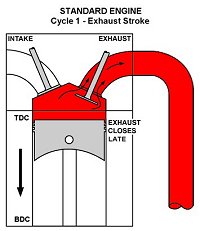

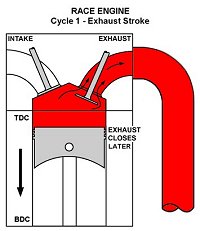

Cycle 1 Exhaust Stroke

|

|

Cycle 3 Intake Stroke - Primary Induction Cycle

|

|

|

|

Cycle 4 Intake Stroke - Secondary Induction Cycle

|

=

|

Cycle 2 Intake Stroke

|

|

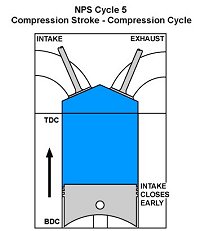

Cycle 5 Compression Stroke - Compression Cycle

|

=

|

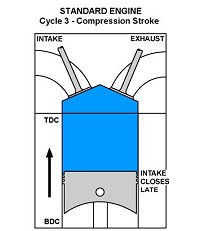

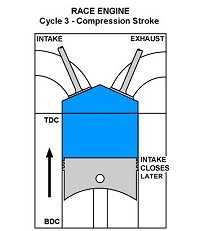

Cycle 3 Compression Stroke

|

|

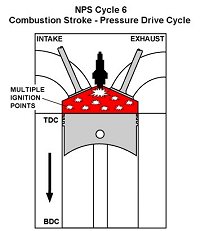

Cycle 6 Combustion Stroke - Pressure Drive Cycle

|

=

|

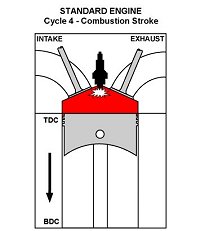

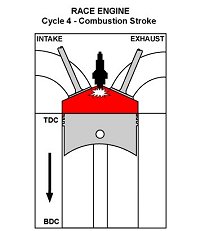

Cycle 4 Combustion Stroke

|

|

For more details see Operating Principles of NPS

NPS 6 cycle process compared to the old 4 cycle process

After 130 years of refinement the old 4 cycle process used by today?s engines produce a lot more horsepower over a narrow high rpm range. However, they also produce poor low rpm torque, high fuel consumption and a lot more pollution. Therefore, to make the old 4 cycle process produce more torque and horsepower over a broader rpm range and reduce its high emissions and fuel consumption, today?s street engines have become a nightmare of mechanical complexity and emission controls.

The NPS 6 cycle process is a lot more efficient than the old 4 cycle process. It produces substantially more torque and horsepower and much lower fuel consumption and emissions over a lower and wider rpm range. The NPS 6 cycle process achieves this using a unique combination of mechanically simple parts and NO emission controls. This eliminates the need to make engines mechanically complex in order to improve their efficiency. What?s even more remarkable is that this new 6 cycle process is in its infant stage of development and is currently a lot more efficient than the old 4 cycle process used by today?s engines. Therefore, given the same refinement as today?s engines the NPS 6 cycle process has the potential to improve its rpm range and the efficiency of street engines far beyond the capability of the old 4 cycle process and mechanical complexity.

NPS Cycle 1 Combustion Stroke ? Pressure Release Cycle

|

Negative Pressure Supercharging

As the exhaust valve opens, the high pressure gas from combustion forces itself through the small and short pipes of the NPS Tri-Y header at twice the gas speed of large pipe headers used by standard and race engines. This produces a much higher vacuum in the small pipe header which pulls the exhaust gases out of the engine and reduces the pressure in the cylinder.

|

Standard and Race Engines

|

This cycle is NOT produced by standard and race engines with large pipe headers and conventional valve timing.

(see next cycle)

|

|

NPS Cycle 2 Exhaust Stroke ? Exhaust Cycle

|

Negative Pressure Supercharging

At the end of the exhaust stroke, the lower pressure (higher vacuum) produced by the NPS Tri-Y header is trapped in the combustion chamber during the overlap period by...

|

•

|

Closing the exhaust valve early before TDC

|

|

•

|

Using less overlap duration

|

|

•

|

Using less exhaust valve lift

|

|

•

|

Synchronising the above 3 valve timing events

|

NOTE

The above 3 valve timing events are part of a more complex valve timing process that requires synchronising 8 valve timing events in order for Negative Pressure Supercharging to work.

|

Standard Engine

(Cycle 1)

The larger pipe headers used by standard engines produce a slow gas speed. This does NOT produce enough vacuum to pull the gases out of the engine or reduce cylinder pressure.

Therefore, at the end of the exhaust stroke the exhaust valve remains open after TDC to allow the piston to push the remaining gases out of the engine.

|

Race Engine

(Cycle 1)

The much larger pipe headers used by race engines produce a slower gas speed than standard engines. This also does NOT produce enough vacuum to pull the gases out of the engine or reduce cylinder pressure.

Therefore, at the end of the exhaust stroke the exhaust valve remains open much longer after TDC than standard engines.

This allows the piston to push the remaining gases out of the engine and the momentum of the gas flow in the large pipe header to help pull the intake charge into the cylinder. However, the effect is small and works ONLY at high rpm.

|

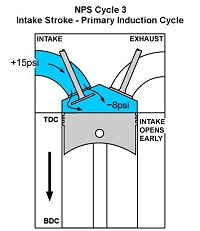

NPS Cycle 3 Intake Stroke ? Primary Induction Cycle

|

Negative Pressure Supercharging

At the beginning of the intake stroke, the intake valve opens early before TDC. This allows the lower pressure (higher vacuum) trapped in the combustion chamber during the overlap period to pull the intake charge into the cylinder BEFORE the piston begins the intake stroke.

As a result the intake charge rapidly fills the cylinder during the EARLY part of the intake stroke.

|

Standard and Race Engines

|

This cycle is NOT produced by standard and race engines with large pipe headers and conventional valve timing.

(see next cycle)

|

|

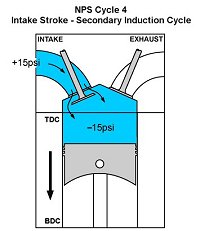

NPS Cycle 4 Intake Stroke ? Secondary Induction Cycle

|

Negative Pressure Supercharging

As the piston moves down the cylinder during the intake stroke, it further reduces the pressure (increases the vacuum) in the cylinder in addition to the lower pressure (higher vacuum) trapped in the combustion chamber during the overlap period.

As a result the higher vacuum...

|

•

|

Pulls a larger intake charge into the cylinder at a higher velocity during the EARLY part of the intake stroke

|

|

•

|

Produces violent air turbulence with NO restriction to air flow

|

|

•

|

Creates a homogenous intake charge that burns faster and cleaner

|

|

•

|

Allows large intake ports and valves with high lift to flow a larger volume of air into the cylinder from 1000-4500 rpm than small intake ports and valves with low or high lift

|

|

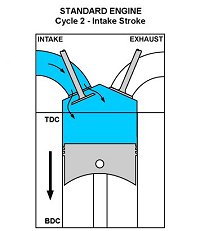

Standard Engine

(Cycle 2)

As the piston moves down the cylinder during the intake stroke, it reduces the pressure (creates a vacuum) in the cylinder.

This pulls the intake charge into the cylinder during the LATE part of the intake stroke.

|

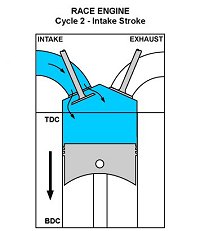

Race Engine

(Cycle 2)

As the piston moves down the cylinder during the intake stroke, it reduces the pressure (creates a vacuum) in the cylinder like the standard engine.

This also pulls the intake charge into the cylinder during the LATE part of the intake stroke.

|

NPS Cycle 5 Compression Stroke ? Compression Cycle

|

Negative Pressure Supercharging

At the end of the intake stroke, the intake valve closes early after BDC to...

|

•

|

Trap the larger intake charge pulled into the cylinder during the EARLY part of the intake stroke

|

|

•

|

Prevent the larger intake charge from being forced back into the intake manifold during the compression stroke

|

|

Standard Engine

(Cycle 3)

Because standard engines pull the intake charge into the cylinder during the LATE part of the intake stroke, the intake valve closes late after BDC to allow more air to fill the cylinder.

This produces more horsepower at high rpm. However, at low rpm the late closing intake valve allows the piston to force the intake charge back into the intake manifold during the compression stroke.

As a result the late closing intake valve substantially reduces low rpm torque.

|

Race Engine

(Cycle 3)

Because race engines also pull the intake charge into the cylinder during the LATE part of the intake stroke, the intake valve closes much later after BDC to allow even more air to fill the cylinder.

This produces even more horsepower at high rpm than standard engines. However, at low rpm the much later closing intake valve allows the piston to force a lot more of the intake charge back into the intake manifold during the compression stroke.

As a result the much later closing intake valve reduces low rpm torque substantially more than standard engines.

|

NPS Cycle 6 Combustion Stroke ? Pressure Drive Cycle

|

Negative Pressure Supercharging

Negative Pressure Supercharging pulls a larger intake charge into the cylinder from 1000-4500 rpm than standard and race engines.

This allows Negative Pressure Supercharging to produce a lot more torque and horsepower over a broader rpm range.

However, the larger intake charge is more difficult to ignite the colder the air induction temperature BELOW 40°C (104°F).

Therefore, Negative Pressure Supercharging uses...

|

•

|

Hot Air Induction to increase the speed of combustion to just BEFORE the point of self ignition in order to increase combustion pressure

|

|

•

|

Cold Cooling System to maintain the optimum combustion temperature and burn rate in order to increase combustion pressure and prevent the hotter and faster burn from igniting prematurely

|

|

•

|

Special Ignition Timing to prevent the hotter and faster burn from igniting prematurely

|

|

Standard Engine

(Cycle 4)

Standard engines pull a larger intake charge into the cylinder from 4000-5500 rpm than from 1000-3500 rpm.

Therefore, standard engines produce more horsepower over a narrow high rpm range but sacrifice performance in other areas such as...

|

•

|

Low torque and slow acceleration from 1000-3500 rpm

|

|

•

|

Poor towing power

|

|

•

|

High fuel consumption

|

|

•

|

High emissions

|

To improve poor low speed torque and acceleration, standard engines use long ram intake manifolds, variable valve timing or high stall converters. This is NOT needed with the much higher torque and faster acceleration produced by Negative Pressure Supercharging.

Also, to reduce the high emissions produced by poor combustion, standard engines use a lot of emission controls. This is NOT needed with the CLEAN burn HTCSI combustion produced by Negative Pressure Supercharging.

|

Race Engine

(Cycle 4)

Race engines pull a much larger intake charge into the cylinder from 5500 to 7000 rpm than from 1000-5000 rpm.

Therefore, race engines produce a lot more horsepower over a narrow high rpm range but sacrifice performance in other areas such as...

|

•

|

NO torque and NO acceleration from 1000-5000 rpm

|

|

•

|

NO towing power

|

|

•

|

Much higher fuel consumption

|

|

•

|

Much higher emissions

|

This is the reason race engines are NOT practical or allowed for street use.

|

Hot Air Induction is also produced by supercharger and turbocharger air pumps

A fact easily overlooked with supercharger and turbocharger air pumps is that they generate so much heat they produce a hot intake charge. For more details click here

| Impulse Engine Technology

P/L |

PO Box 986 Randwick NSW 2031 Australia

Ph: (02) 9398 5544

Fax: (02) 9398 5644

International: Ph: +(612) 9398 5544

Fax: +(612) 9398 5644

Email Us

Inventor of Negative Pressure Supercharging

|

|

|